Are you ready to introduce yourself?

Show the world what you're made of 💪

Effortlessly showcase your accomplishments because being awesome 😎 deserves a spotlight.

Create

Effortlessly build an online portfolio to showcase your accomplishments.

Share

Share your online portfolio and broadcast your successes to the world.

Connect

Expand your professional circle and forge meaningful relationships.

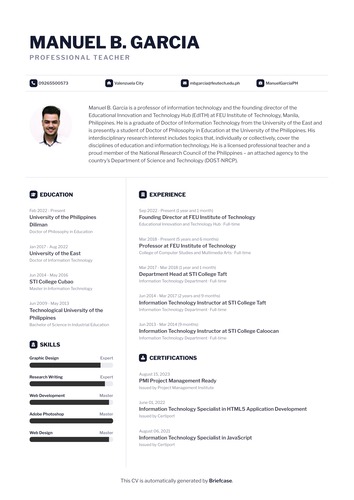

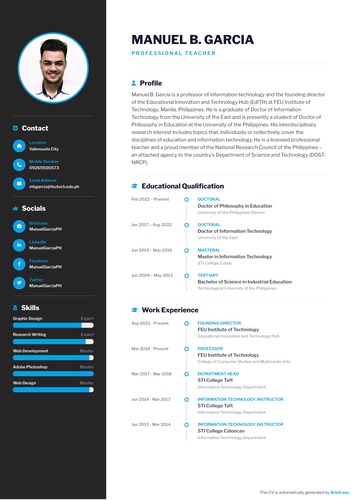

Building Your Career, One CV at a Time

Create Your Professional CV

Say goodbye to the hassle of manual formatting and updates, and start elevating your professional journey with Briefcase's automatic CV generator.

Seamlessly convert your achievements, skills, and experiences into a polished document suitable for job applications, interviews, and networking.

Streamlined Process

Save time and effort by automatically converting your online portfolio content into a well-structured CV.

Professional Formatting

Your CV will maintain a professional look and feel, ensuring you make a strong impression on potential employers.

Versatile Usage

Use your CV for job applications, networking, or any situation where you need to showcase your qualifications.

Always Up-to-Date

Your CV stays current with your latest achievements as you update your portfolio, eliminating the need for manual updates.

Spotlight on Briefcase Users

Here are a few of the incredible tamaraws who have embraced our platform to showcase their skills and accomplishments.

Ma. Joanna D. Guevarra

BSCSSE Student at FEU Institute of Technology

Jasmine Lenzy T. Tan

Multimedia Arts Student

Kelgeen Jan L. Penilla

BS IT Specialization in Web and Mobile Application

Jenimille T. Ortile

Multimedia Artist specializing in digital illustration and story writing.

Eadward Andrei D. Lladoc

A tutee of FEU Institute of Technology taking up BSIT - specialized in Business Analytics

Alyanna Ruth B. Dela Torre

Alyanna Ruth B. Dela Torre

Gabriel B. Cortez

IT Student seeking Internship

Ivan Andrei G. Mallanao

BSITWMA student at FEU Institute of Technology

Frequently Asked Questions

Ready to show the world?

Join the movement of tamaraws who showcase their accomplishments and show the world what they're made of.

Get started — it’s freeJoin 18896 tamaraws today and start showcasing.